The selection of appropriate standards for pipe fittings is a critical decision in the engineering and construction of fluid transport systems. The thickness of the pipe is a fundamental parameter that influences this choice, as it directly affects the structural integrity and safety of the system. This article explores how pipe thickness can guide the decision between adopting European (EN) standards or national standards, such as those from the American Society of Mechanical Engineers (ASME) and the American National Standards Institute (ANSI) in the United States.

The Significance of Pipe Thickness

Pipe thickness is a key determinant of a pipe’s ability to withstand internal pressures, external loads, and environmental factors such as temperature fluctuations and potential for corrosion. A thicker pipe wall provides increased strength and durability but may also add to the cost and weight of the system.

European (EN) Standards

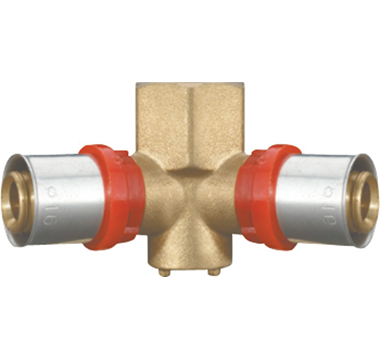

European standards, such as EN 10255 and EN 10208, are designed to ensure a high level of safety and reliability across the EU. These standards often specify minimum wall thicknesses for pipes to meet various pressure ratings and service conditions. The stringent requirements of EN standards reflect a conservative approach to safety, which may necessitate thicker pipes for certain applications.Our EN compliant pipe fittings include:

National (ASME/ANSI) Standards

In contrast, ASME/ANSI standards, including ASME B31.3 and ANSI/ASME B16.5, offer a broader range of options that can accommodate different engineering needs and economic considerations. These standards may allow for thinner pipes where the operating conditions and risk assessments justify their use. The flexibility of national standards reflects an approach that balances safety with economic and practical considerations.Our ASME/ANSI compliant pipe fittings include:

Factors Influencing the Choice of Standards

The decision to choose between European and national standards based on pipe thickness involves a multifaceted analysis of:

- (1)The operating pressure and temperature of the system.

- (2)The material properties of the pipe, including its strength and corrosion resistance.

- (3)The specific application, such as chemical processing, oil and gas transport, or municipal water supply.

- (4)Regulatory requirements and compliance within a particular region or industry.

- (5)The economic implications of material costs, installation, and maintenance.

- (6)Long-term performance and durability expectations.

Other factors affecting the piping system

The statement “The thickness of the pipe determines whether to choose European standard or national standard” is a simplification of a complex decision-making process. While pipe thickness is a significant factor, it is not the sole determinant when selecting between European (EN) and national (such as ASME/ANSI for the United States) standards for pipe fittings. Below are several factors that must be considered together with pipe thickness:

In summary, while the thickness of the pipe is an important consideration, it is one of many factors that must be evaluated when choosing between European and national standards for pipe fittings. The final decision should be based on a comprehensive assessment that takes into account all relevant factors to ensure the safety, reliability, and economic viability of the pipe system.