BORNIC Compression Fittings

Engineered for High-Pressure Precision, Built to Last

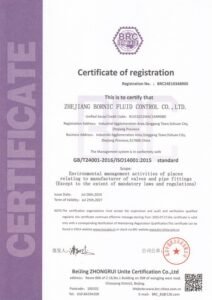

20+ Years | 300+ Machines | Global Certifications

Why BORNIC?

✅ Unmatched Strength. Withstands 25+ bar pressure & extreme vibrations.

✅ Zero-Leak Guarantee. Precision threads meet ISO 1179 & DIN 3852 standards.

✅ Reusable & Cost-Effective. Durable design allows disassembly without wear.

✅ Customize NPT/BSPP/Metric sizes (OEM/ODM supported).

Don’t see your ideal fittings? Click ‘Request Customization’ to submit technical drawings.

Want more information about Compression Fittings ? Download our catalogue

Some questions about Compression Fittings

Our fittings support multiple thread standards to meet global demands:

NPT (ANSI/ASME B1.20.1) for North America.

BSPP (G) and BSPT (R) (ISO 228/ISO 7) for Europe and Asia.

Custom threading is available upon request.

Yes, all BORNIC brass Compression Fittings are certified to NSF/ANSI 61 for potable water and WRAS Approved (UK). We use lead-free C37700/CW617N brass alloys with ≤0.1% lead content, fully compliant with EU Regulation (EU) 2023/915. Certificates available upon request.

Yes. Our brass fittings are NSF/ANSI 61 certified and WRAS-approved, ensuring safe use in potable water applications. We use lead-free alloys (≤0.25% lead content) compliant with:

EU Regulation (EU) 2023/915 (replacing Directive 98/83/EC).

California’s AB1953 and the US Safe Drinking Water Act.

Absolutely. We specialize in custom-engineered solutions:

Bespoke dimensions, thread types, and pressure ratings.

Prototyping support with 3D CAD files (STEP, IGES).

Material certifications and test reports provided.

Standard Lead Time: 4–6 weeks for orders up to 50,000 units.

Expedited Service: We offer a 2–3 week rush option for urgent projects.

Absolutely. As a Tier 1 supplier for global plumbing brands, we specialize in:

Design: Custom threading (NPT/BSP), logos, surface finishes (chrome/nickel plating), and packaging.

Material Modifications: Lead-free (RoHS), dezincification-resistant (DR Brass), or specialized alloys.

Prototyping: 3D-printed samples within 72 hours and DFM (Design for Manufacturing) feedback.

Certification Assistance: NSF/WRAS/UL certifications tailored to your market.

Yes, we provide detailed installation guides with every Compression Fittings order, including step-by-step instructions, torque specifications, and compatibility charts for PEX, copper, and stainless steel pipes. Our technical support team is available 24/7 to assist with installation challenges, system design optimization, or leak-testing procedures.

Hello, this is Johanna from Bornic. I'm pleased to answer your questions.

To get the latest product information.

WhatsApp Us

🟢 online

WhatsApp us