BORNIC Screw Fittings

Engineered for High-Pressure Precision, Built to Last

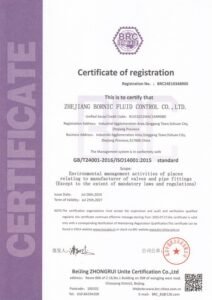

20+ Years | 300+ Machines | Global Certifications

Why BORNIC?

✅ Unmatched Strength. Withstands 25+ bar pressure & extreme vibrations.

✅ Zero-Leak Guarantee. Precision threads meet ISO 1179 & DIN 3852 standards.

✅ Reusable & Cost-Effective. Durable design allows disassembly without wear.

✅ Customize NPT/BSPP/Metric sizes (OEM/ODM supported).

Don’t see your ideal fittings? Click ‘Request Customization’ to submit technical drawings.

Want more information about Screw Fittings? Download our catalogue

Some questions about Screw Fittings

Our fittings are engineered for multi-material compatibility

Yes, all BORNIC brass screw fittings are certified to NSF/ANSI 61 for potable water and WRAS Approved (UK). We use lead-free C37700/CW617N brass alloys with ≤0.1% lead content, fully compliant with EU Regulation (EU) 2023/915. Certificates available upon request.

We offer 3 free samples of standard fittings .

We produce 15+ thread types on-demand:

Common Standards: NPT, BSPP, BSPT, JIS, Metric.

Hybrid Adapters: NPT-to-BSP cross-thread designs (DN15-DN50).

Special Threads: SAE inverted flare, UN/UNF.

Standard Lead Time: 4–6 weeks for orders up to 50,000 units.

Expedited Service: We offer a 2–3 week rush option for urgent projects.

Absolutely. As a Tier 1 supplier for global plumbing brands, we specialize in:

Design: Custom threading (NPT/BSP), logos, surface finishes (chrome/nickel plating), and packaging.

Material Modifications: Lead-free (RoHS), dezincification-resistant (DR Brass), or specialized alloys.

Prototyping: 3D-printed samples within 72 hours and DFM (Design for Manufacturing) feedback.

Certification Assistance: NSF/WRAS/UL certifications tailored to your market.

Yes, we provide detailed installation guides with every screw fitting order, including step-by-step instructions, torque specifications, and compatibility charts for PEX, copper, and stainless steel pipes. Our technical support team is available 24/7 to assist with installation challenges, system design optimization, or leak-testing procedures.

Hello, this is Johanna from Bornic. I'm pleased to answer your questions.

To get the latest product information.

WhatsApp Us

🟢 online

WhatsApp us