Press fittings manufacturer

For 20+ years, BORNIC has delivered high-performance Press Fittings trusted in plumbing, HVAC, and industrial systems worldwide.

Key Advantages

– Robust Durability: Withstands 16 bar pressure and -20°C to 110°C extremes.

– Zero-Leak Guarantee: Precision-tested with advanced equipment for perfect seals.

– Fast Installation: Compatible with all major press tools, cutting labor time by 50%.

– Custom Sizes: Standard (15mm-108mm) or OEM/ODM solutions available.

Scalable Quality, Competitive Pricing

300+ machines ensure bulk orders meet deadlines without compromising standards.

Don’t see your ideal fittings? Click ‘Request Customization’ to submit technical drawings.

Want more information about Press fittings? Download our catalogue

Some questions about Press fittings

At BORNIC, we guarantee dimensional precision through a combination of advanced CNC machining, automated optical inspection (AOI) systems, and strict adherence to ISO 2768 tolerance standards. Our production process includes:

First-Article Inspection (FAI): 100% verification of initial samples using CMM (Coordinate Measuring Machines).

In-Process Checks: Real-time monitoring with laser micrometers (±0.01mm accuracy).

Material Certification: Only certified C37700/CZ121 brass alloys are used to minimize thermal expansion variances.

Standard Lead Time: 4–6 weeks for orders up to 50,000 units.

Expedited Service: We offer a 2–3 week rush option for urgent projects.

Absolutely. As a Tier 1 supplier for global plumbing brands, we specialize in:

Design: Custom threading (NPT/BSP), logos, surface finishes (chrome/nickel plating), and packaging.

Material Modifications: Lead-free (RoHS), dezincification-resistant (DR Brass), or specialized alloys.

Prototyping: 3D-printed samples within 72 hours and DFM (Design for Manufacturing) feedback.

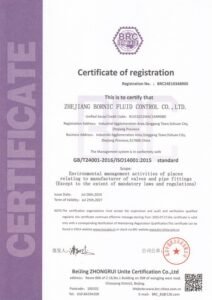

Certification Assistance: NSF/WRAS/UL certifications tailored to your market.

Yes, we provide detailed installation guides with every brass press fitting order, including step-by-step instructions, torque specifications, and compatibility charts for PEX, copper, and stainless steel pipes. Our technical support team is available 24/7 to assist with installation challenges, system design optimization, or leak-testing procedures.

Hello, this is Johanna from Bornic. I'm pleased to answer your questions.

To get the latest product information.

WhatsApp Us

🟢 online

WhatsApp us