Rugged cover Abrasion resistant Flexibility Won’t kink under water pressure

Rugged cover Abrasion resistant Flexibility Won’t kink under water pressure

WHO WE ARE

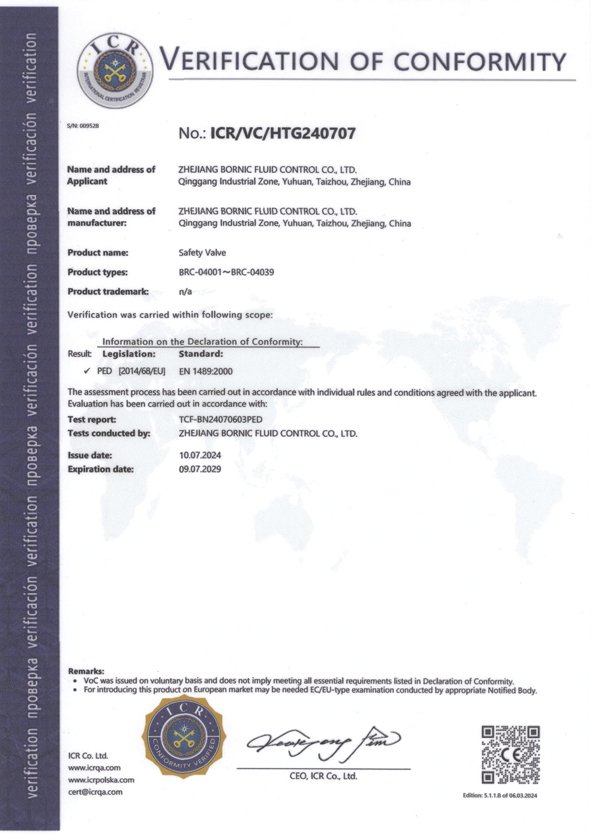

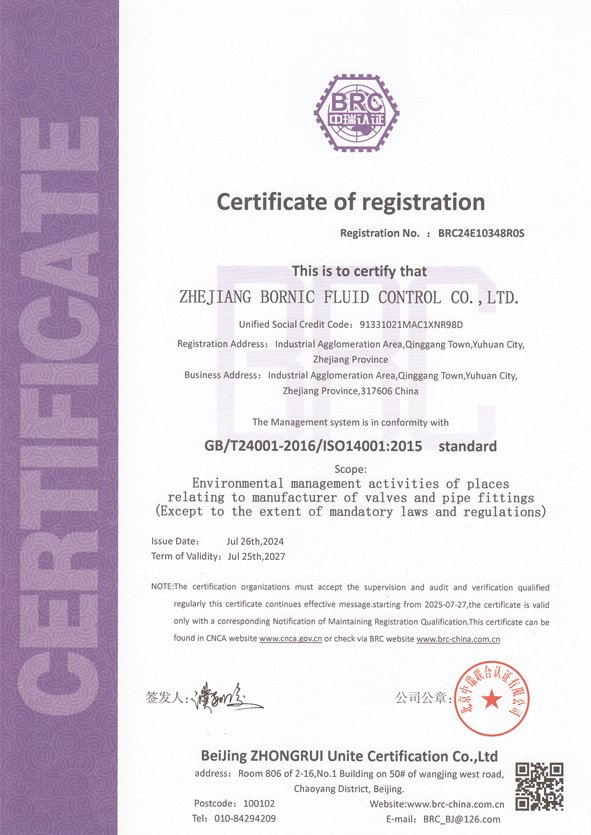

Founded in 2003, BORNIC is a seasoned industry leader offering a wide range of tubing solutions for wholesalers, engineering contractors, and other brands. With our extensive international connections and quality certifications, we seamlessly deliver plumbing parts to your regions. Our unwavering commitment to quality tubing services has been proven time and again.

Market Expertise

Robust Supply Chain

Efficient Management

In-House Factory and Facilities

WHO WE ARE

Founded in 2003, BORNIC is a seasoned industry leader offering a wide range of tubing solutions for wholesalers, engineering contractors, and other brands. With our extensive international connections and quality certifications, we seamlessly deliver plumbing parts to your regions. Our unwavering commitment to quality tubing services has been proven time and again.

Market Expertise

Robust Supply Chain

Efficient Management

In-House Factory and Facilities

BORNIC provides expert brass CNC machining services, drawing on extensive experience to deliver custom solutions tailored to your specific needs. We offer a selection of brass grades, allowing you to choose the best option for your requirements.

| TEM | PROCESS CAPABILITY PARAMETER |

|---|---|

| Product | Fitting, Valve, Stainless Steel Manifold |

| Material | Brass, Stainless Steel, Bronze, Copper, Lead-free copper, Aluminum |

| Surface Treatment | Pickling, Natural color, Sandblasting, Nickel plating, Chrome plating |

| Size | 1/2, 3/4, 1/4, 3/8, 1/8, 1, 2, 1 1/4, 1 1/2, 2 1/2 (Customization supported) |

| Warranty | 5 years |

| MOQ | 10 Pcs |

| LOGO customization | Laser marking, labeling |

Brass is a popular material for CNC machining because of its excellent machinability, aesthetic appeal, and corrosion resistance. Below are some common brass grades frequently used in CNC machining, each selected for their unique properties and suitability for different applications:

C36000, commonly known as “Free-Cutting Brass” or “360 Brass,” is a widely used alloy in the brass family, prized for its exceptional machinability. Composed of approximately 61.5% copper, 35.5% zinc, and 3% lead, C36000 is specifically formulated to facilitate high-speed machining operations.

Key Properties:

C37700, commonly known as “Forging Brass,” is a highly regarded alloy in the brass family, especially favored for its excellent forging capabilities. This alloy typically consists of approximately 57% copper, 3% lead, and the remainder is zinc, which collectively contribute to its desirable properties for various applications.

Key Properties:

C38500, also known as “Architectural Bronze” or “Free-Cutting Brass,” is a popular alloy in the brass family known for its excellent machinability and aesthetic appeal. Composed of approximately 55-59% copper, 0.5-2.5% lead, and the remainder zinc, C38500 is widely used in applications requiring precise machining and an attractive finish.

Key Properties:

C27000, commonly referred to as “Yellow Brass,” is a popular alloy known for its high ductility, attractive appearance, and good corrosion resistance. This alloy typically consists of approximately 65% copper and 35% zinc, and it lacks the lead additives found in other machinable brasses, which affects its properties and applications.

Key Properties:

Discover our collection of CNC machined brass parts, where precision meets craftsmanship. Our showcase highlights a diverse array of components crafted from premium brass, each meticulously tailored to meet exacting industry standards.

1. Polishing: Removing oxides and imperfections to achieve a smooth, mirror-like surface finish.

2. Plating: Applying layers of nickel, chrome, or gold to enhance aesthetics and provide corrosion resistance.

3. Passivation: Removing surface contaminants to improve corrosion resistance.

4. Powder Coating: Applying a protective and decorative layer that cures at high temperatures to create a durable finish.

5. Anodizing: Increasing surface hardness and wear resistance through controlled oxidation.

6. Brushed Finish: Using a fine bristle brush on a belt or wheel to achieve a satin finish with distinct linear patterns.

7. Bead Blasting: Spraying brass with small beads at high pressure to achieve a uniform matte finish.

8. Engraving: Creating patterns or text on the brass surface using laser engraving for decorative or functional purposes.

Yes, our company is very pleased to send you free samples for quality test as long as freight cost being paid by buyers themselves.

We accept 10 piece as the minimum order quantity.

Yes, we have more than 4 years export experience, we can do FOB, C&F, CIF, DDU and DDP

For small testing orders, we accept Paypal, Western Union, T/T and Credit Card. For mass orders, we accept T/T and L/C.

Standard: mass orders will be packed by many carbon boxes and filled in plywood cases.

Available requirement: blister packing for every piece of product, plastic caps for clamp connected products.

For inquiries about our products or price list, please leave to us and we will be in touch within 24 hours

Fitting

Valve

HVAC Series

Home

About

Product

Blog

Contact

Hello, this is Johanna from Bornic. I'm pleased to answer your questions.

To get the latest product information.

WhatsApp Us

🟢 online

WhatsApp us

Hello, this is Johanna from Bornic. I'm pleased to answer your questions.

To get the latest product information.

WhatsApp Us

🟢 online

WhatsApp us